What is Sublimation Printing?

If you are looking for a way to print designs and protect the environment, sublimated printing may be for you. While it is expensive starting out, depending on your needs, sublimated printing is cost-effective in the long run. Sublimated printing dates back decades, with its origins in France. Sublimated printing is a fairly new form of printing. If you want to learn more about sublimated printing, please continue reading this article.

If you are looking for a way to print designs and protect the environment, sublimated printing may be for you. While it is expensive starting out, depending on your needs, sublimated printing is cost-effective in the long run. Sublimated printing dates back decades, with its origins in France. Sublimated printing is a fairly new form of printing. If you want to learn more about sublimated printing, please continue reading this article.

What is Sublimation Printing?

Sublimation printing is a form of digital printing that uses sublimation paper. It is also known as sublimation transfer paper or sublimation copy paper. What is more, sublimated printing is also known as dye sublimation. Although the process is fairly beginner-friendly, you will need a printer that allows sublimation and can take sublimation ink cartridges. There are many sublimation printing tutorials online. Many printing businesses, including ours, specialize in this special kind of printing.

History:

In ancient times, printing onto cloth involved using stamps. These were typically fashioned from different types of metal. Although in Mesopotamia, clay stamps were also used. The seals and small stamps made it possible to print off identical images for decoration or identification.

As printing technology developed, printing became easier in bulk using the stamp technique. Woodblock printing came next for printing text, images, and patterns. It first began in East Asia and China as a method of textile printing.

In the late 1950s, sublimated printing developed in France, and in the 1970s through the 1980s, the United States already had its own computer-based sublimation printers.

What is sublimation?

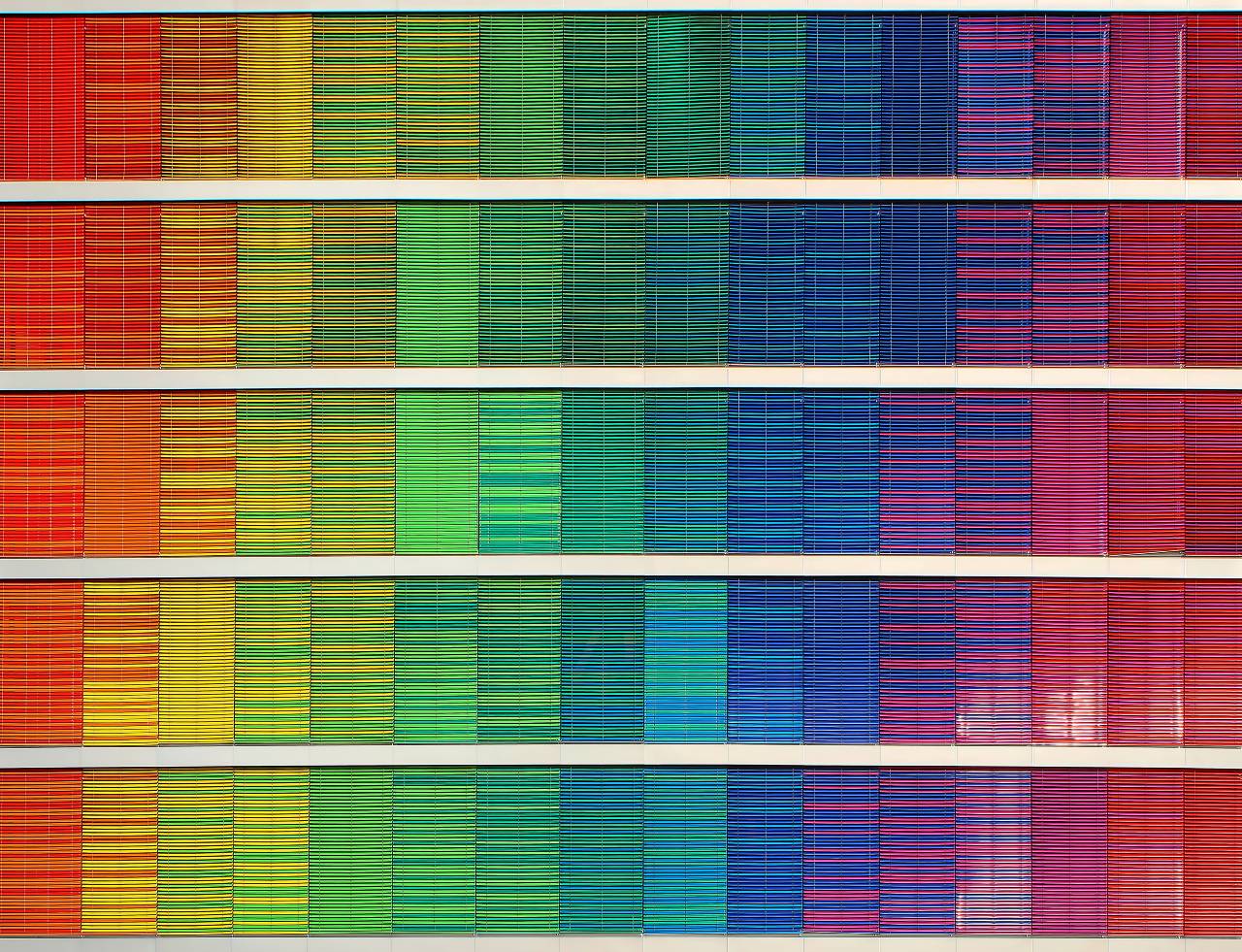

Sublimation is a chemical process in which a solid transforms into a gas. It was a common belief that sublimation skips the liquid state, but it was disproven. The correct term is dye-diffusion. The dye-sublimation process naturally lends itself to photography because it results in higher visual quality. This is due to a thermal transfer where the high temperature results in dye being vaporized and imbued onto the surface. The molecular bonding process begins, which adheres the dye to the surface and creates a permanent transfer. When the dyes return to their solid form, they appear glossy and bright. Since the dye is bonded with the surface, it makes the print less susceptible to warping or fading.

How to do sublimation printing?

Sublimation printer uses: Sublimated printing occurs when your design is printed onto sublimation paper. Then, it's printed as a mirror image, using dye-sub inks – water-based inks that are environmentally friendlier than harsh chemical inks. After that, the image lines up with the fabric, and heat (between 350 – 400 degrees Fahrenheit) and pressure are applied. Ink transitions directly from a solid into a gas. The inks then enter the fibers of the material and permanently bond to the fibers.

What Products Can You Sublimate?

The following items can be sublimated: ceramic mugs, ceramic tiles, Medium Density Fiberboard (MDF) coasters, glass sheets, aluminum sheets, polyester mouse mats, polyester cushion covers, polyester aprons, and polyester bags. Items such as skateboards, car hoods, floor mats, and promotional posters are some of the best items that you can sublimate.

The pros and cons of subliminal printing:

The pros of sublimation printing are the following: The color permanently transfers to the fabric; The ink immediately dries; Very durable; The design is texture-free, even when it's all over the object sublimated; Prints in full colors, which is perfect for photos; The inks are very UV-resistant, and sublimation transfers only the ink to the fabric. Another benefit of this type of printing is that the inks don't use as much water as other printing forms.

A con of sublimation printing is that it only works on light-colored, synthetic fabrics with a poly content of 85 percent or higher. Therefore, you cannot sublimate onto black fabrics. Another con of sublimination is that set-up is more expensive than the process itself. The major con of this type of sublimation printing is that it is costly. While dye-sublimation printers are made for household and professional use, they can cost around $300 to $600. Sublimation printers for mass production can cost up to $10,000.

Other required products include a heat press and printing paper, which are just as expensive. Well-made heat presses can cost from $150 to $500, and the sublimation paper used for the printer can cost at least $100 depending on the amount that you will need.

Compared to the printers themselves, you must buy sublimation paper sparingly. The price of this equipment will benefit you in the long run when it comes to print quality.

As expressed before, another con is that this type of printing is mostly one on polyester fabrics. Fabrics need to be 100% polyester for the best outcome. If you want to print on items that aren't fabric, they must be poly-coated for the best results. Fabrics that are 100% cotton will not fare well with this type of printing.

Can I sublimation printing white on black?

Unfortunately, because sublimation works best on light-colored items, specifically the color white, you cannot sublimation printing white on the color black.

What's the difference between sublimation printing and digital printing?

The difference between sublimation and digital printing is that digital prints are printed on the material's surface, whereas dye sublimation fuses into the material. This means that it's difficult to damage something sublimated.

Summary:

Sublimation printing is a form of digital printing that requires the use of sublimation paper. Sublimation allows more room for creativity and allows for unique designs utilizing full-color printing. Sublimation printing is faster compared to screen printing. Sublimation is perfect for intricate, complex designs.

In a day, once the sublimination print is made, one can make thousands of prints. The technique takes advantage of technology, which is what adds to its fastness. The only thing you will have to worry about is a shortage of electricity. With a constant source of power, however, results are produced within hours.